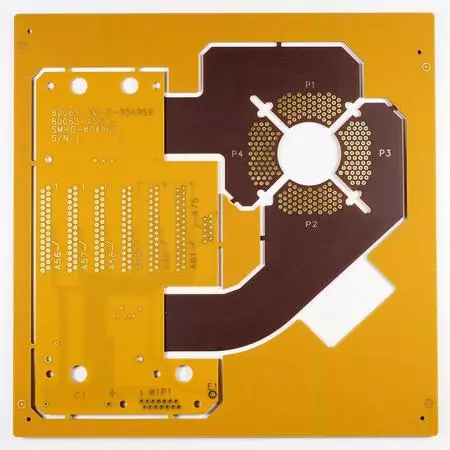

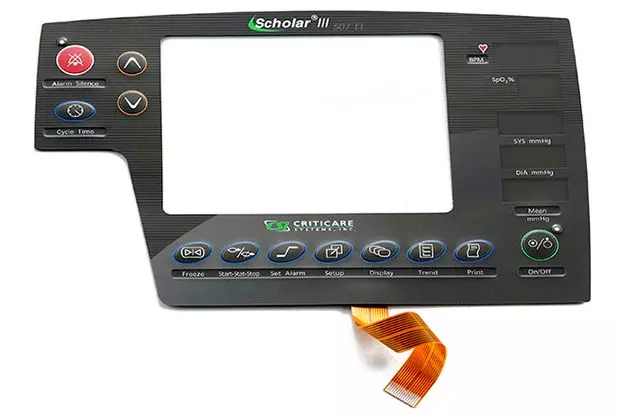

Industry use Printed Circuit Board

Printed Circuit Board 0503

Sigle sided printed circuit board, PCB , RF pcb, Rigid PCB, Multilayer PCB

The first PCBs used through-hole technology, mounting electronic components by leads inserted through holes on one side of the board and soldered onto copper traces on the other side. Boards may be single-sided, with an unplated component side, or more compact double-sided boards, with components soldered on both sides. Horizontal installation of through-hole parts with two axial leads (such as resistors, capacitors, and diodes) is done by bending the leads 90 degrees in the same direction, inserting the part in the board (often bending leads located on the back of the board in opposite directions to improve the part's mechanical strength), soldering the leads, and trimming off the ends. Leads may be soldered either manually or by a wave soldering machine.

Applications

- overhead projector

- Dehumidifier

- Related Products

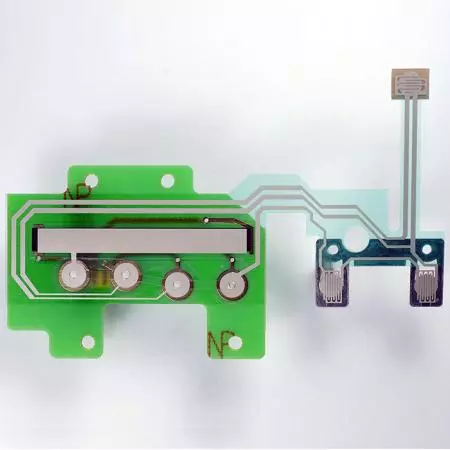

PCB combine with silver printed circuit

Printed Circuit Board 0504

Alternatives to PCBs include wire wrap and point-to-point construction, both once popular but now rarely...

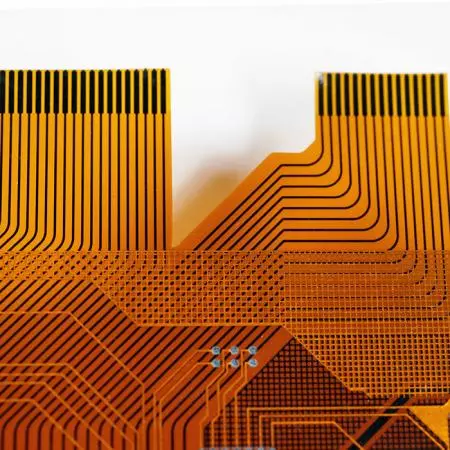

DetailsMulti-layer Flexible Printed Circuit

Flexible Printed Circuit 0205

According to the layer of Cu, Multi-layer Flexible Printed Circuitcan be single sided, double...

Details

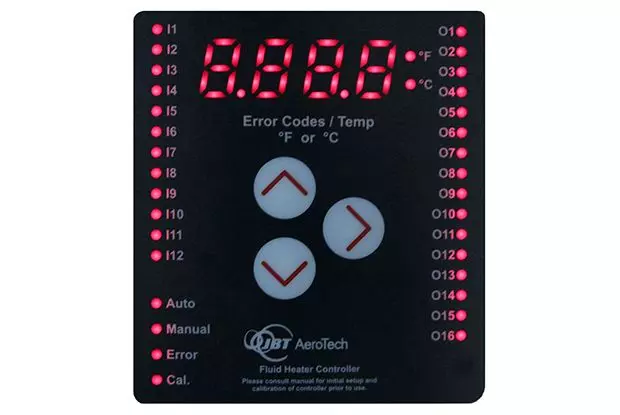

Industry use Printed Circuit Board | Durable Keypads for Any Environment - Manufacturer Direct | YiYi Enterprise Co., Ltd

Located in Taiwan since 1974, Yi Yi Enterprise Co., Ltd. has been a membrane switch manufacturer. Their main products include, Industry use Printed Circuit Board, waterproof membrane switches, membrane switch keyboards, tactile membrane keypads, graphic design overlay, mechanical membrane keyboards, custom aluminum nameplates, cutout EL panels, industrial silicone rubber keypads and rigid-flex PCB design and fabrication, and all the materials and components are RoHS compliant.

Yi Yi is expert in manufacture of membrane keyboard switches, flexible printed circuits, rigid-flex board, el panels, silicone rubber keypad and name plates. We have acquired the skills and technology necessary to produce top-quality products that are suitable for use in computers, instruments and other electronic and electrical goods.

YI YI has been providing customers with membrane switches, both with advanced technology and 49 years of experience, YI YI ensures that each customer's requirements are met.