Company Profile

Guided by a belief that electronics products would become an essential aspect of everyday life in both business and private endeavors, YiYi Enterprise Co., Ltd was founded in 1974 with a medium-sized capital investment, but large-sized devotion to bringing top quality products to customers at affordable prices.

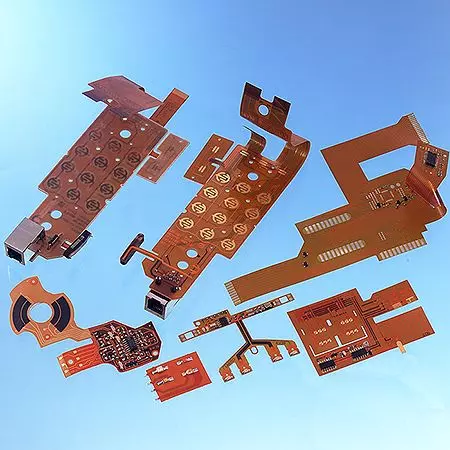

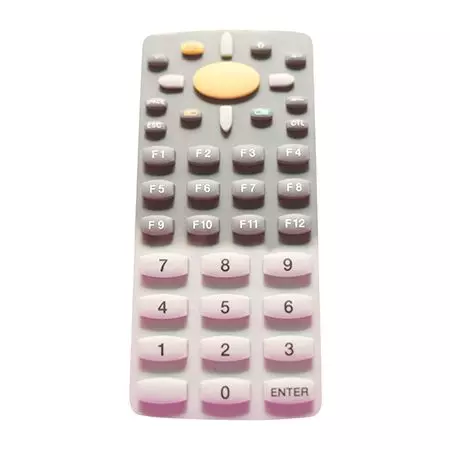

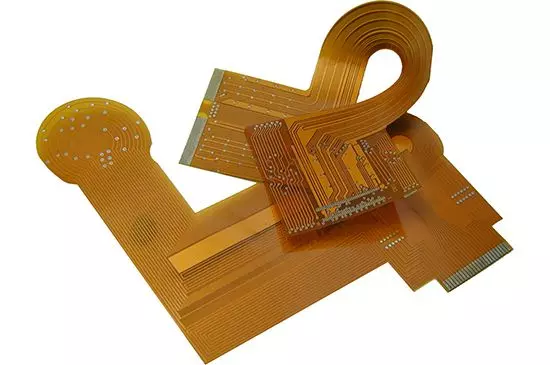

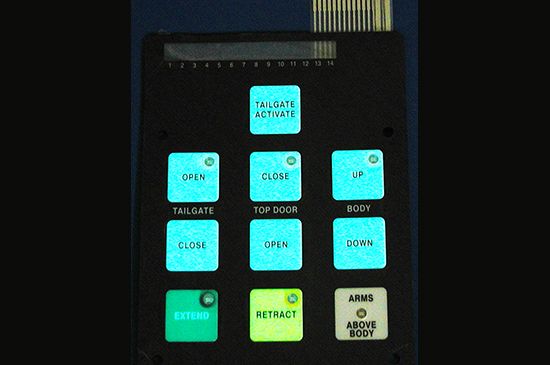

Today, we specialize in manufacturing membrane keyboard switches, flexible printed circuits, rigid-flex boards, EL panels, and silicon rubber keypads and name plates. We pride ourselves on our ability to incorporate the skills and technology necessary to produce top-quality products that are suitable for use in computers, instruments, electronics and electrical goods. We attribute the excellent reputation we've developed in our industry to our experienced R&D departments, our ability to process OEM and ODM orders, and the advanced capability that are large production lines provide.

Due to the fact that we own and operate our two factories locally in Taiwan, we are able to ensure our customers that thorough inspections are carried out at each stage of production as part of our quality assurance policy. Every finished product is fully assessed before delivery, and all of our materials and components are RoHS compliant.

Our commitment to continual excellence and top level quality and service has not only allowed us to develop strong and enduring relationships with our partners and customers, but has also enabled us to develop a reputation in our industry as a trusted leader among our peers and clientele.

FPC Bending Test

Bending- test (Fatigue test) included monotonic bending and cyclic bending. The purpose is to confirm if the solder pads or structure still in good condition under repeat bending. The tester can adjust any angle and speed. If there is any damage in cable or pads, the tester will stop working right away.

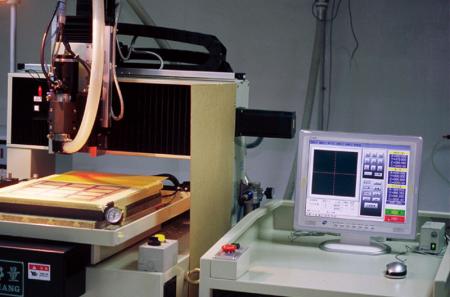

FPC Auto Drilling

CNC transmission positioning with smart operating system. It can automatically arrange the best operating path in a panel, this could save lots of working time and increase productivity. Drill any diameter of holes on FPC board precisely and automatically. The tolerance of drilling holes is within +/-0.05mm.

FPC E-Test

Built-in self-diagnosis system and support automatic verification function. High precision measurement and fast testing. Open-short testing for all the circuit traces between conductive pads and fingers. The equipment can test the circuit in panel size, very fast and precisely.

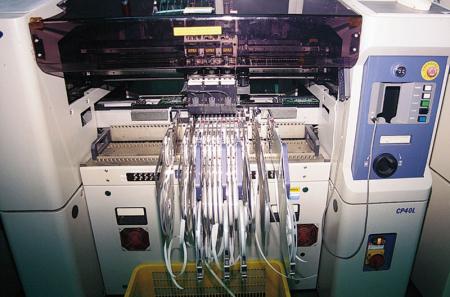

FPC SMT

With system of anti-error components, it can prevent the incorrect parts placed in the machine. Quickly assemble any size of components in a panel automatically. The material of circuit board could be flex or rigid. The file format for the equipment is the standard Gerber file.

CNC Laser Cutting

Use laser light to cut the outline of the project without any tooling, this could lower down the NRE charge. Support software are AutoCad, CorelDraw and Illustrator. Material could be steel, aluminum, polycarbonate, polyester and PVC. Easily and fast operation, suitable for any urgent case.

Color Scanner

Compare the color between golden sample and production, using CMYK value to checking each color. The same color would look different on different material, we can use color scanner to analyze CMYK value and print the right color as customers expect.

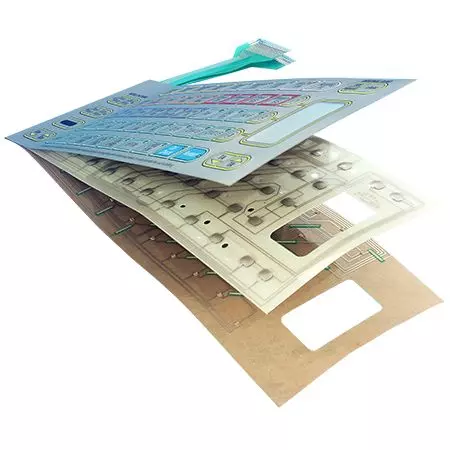

SMT for Membrane Switch

The circuit layer of membrane switch is polyester, it can’t resist high temperature, so we can’t use tin solder paste for SMT. We use conductive silver paste to assemble LED or other components. Our SMT equipment could adjust to lower placing speed and lighter force, in case silver conductive paste spread out causing circuit short failure.

- Certificates

- Video

We are a company with a factory in Taiwan engaged in the business of manufacture, supply and export of all kinds of high quality Flexible Printed Circuits, and Membrane Switches. We have became one of the leading brands in this field. With years of experience in the field of producing. Yi Yi Enterprise Co, Ltd is known by our customers for our outstanding performance .