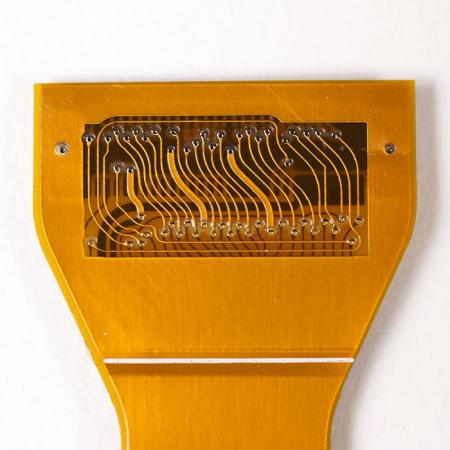

PITCH 0.1mm / GAP 0.08mm FPC

Flexible printed circuit board (FPCB) is a type of circuit board that is made of a flexible...

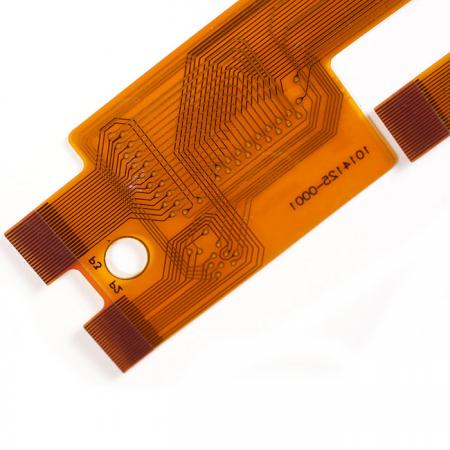

4 Layers Flexible Printed Circuit

4 Layers Flexible Printed Circuit can be single sided, double sided, multilayer, and with SMT (surface-mount...

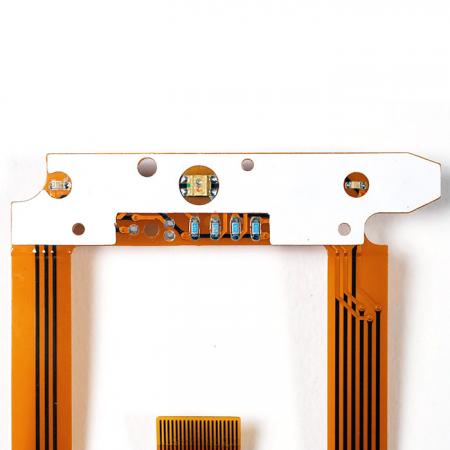

Flexible Printed Circuit with Stiffener

The material of stiffener could be polyimide or polyester. Our Flexible Printed Circuit with...

SMT Flexible Printed Circuit

Double sided FPC. Assembled with components. Our SMT Flexible Printed Circuit can be single...

FPC assembled componets

Flexible Printed Circuit with light guide film. Our FPC products can be single sided, double...

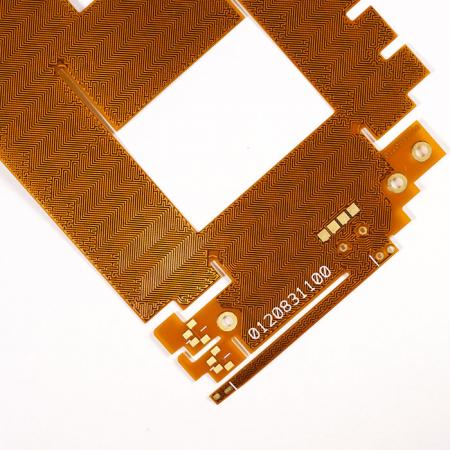

ESD Shielding Flexible Printed Circuit

Double Sided FPC with ESD Shielding Layer. ESD shield can prevent the electrostatic disturbance. Our...

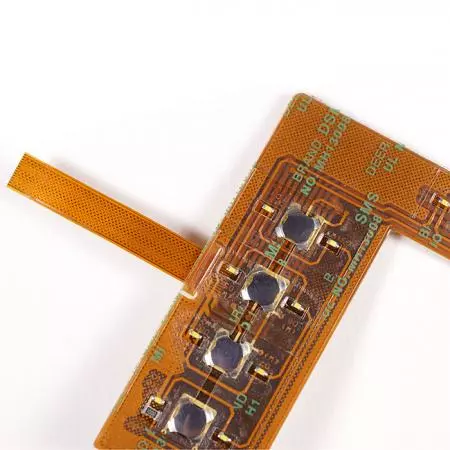

FPC with Metal Dome

Double sided FPC. Assembled with metal dome or SMT any components. Our FPC products can be single...

FPC assembled graphic overlay

Our FPC products can be single side, double side, multilayer, and with SMT (surface-mount technology)...

Membrane Switch with Flexible Printed Circuit

Membrane Switch with Double sided FPC. Our FPC products can be single side, double side, multilayer,...

Controlling device Silicone Rubber Keypad

Controlling device Silicone Rubber Keypad uses the compression molding properties of silicone...

Single button Silicone Rubber Keypad

The technology of Single button Silicone Rubber Keypad uses the compression molding properties...

Poly button Silicone Rubber Keypad

The technology uses the compression molding properties of silicone rubber to create angled...