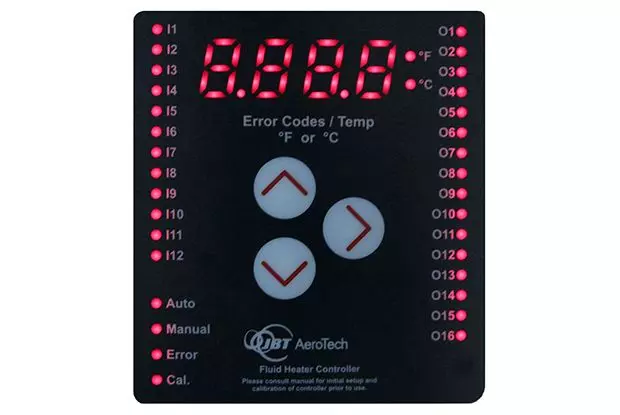

Facilities Translucent Rubber Keypad

Silicone Rubber Keypad 0311

Rubber PCB, Rubber FPC, Silionce rubber assembled, Custom-molded keypad

Facilities Translucent Rubber Keypad uses the compression molding properties of silicone rubber to create angled webbing around a switch center. On depression of the switch the webbing uniformly deforms to produce a tactile response. When pressure is removed from the switch the webbing returns to its neutral position with positive feedback. In order to make an electronic switch a carbon or gold pill is placed on the base of the switch center which contacts onto a printed circuit board when the web has been deformed. It is possible to vary the tactile response and travel of a key by changing the webbing design and / or the shore hardness of the silicone base material. Unusual key shapes can easily be accommodated as can key travel up to 3mm. Tactile forces can be as high as 500g depending on key size and shape.

The snap ratio of a keypad determines the tactile feel experienced by the user. The recommended snap ratio for designers to maintain is 40% - 60%; if dropped below 40% the keys will lose tactile feel but have an increased life. Loss of tactile feel means the user will not receive a "click" feedback during actuation.

Applications

- Nail dryer UV machine

- Telephone

- Gaming

- Security Systems

- Related Products

Rubber Keypad combine with PCB

Silicone Rubber Keypad 0313

Rubber Keypad combine with PCB uses the compression molding properties of silicone rubber...

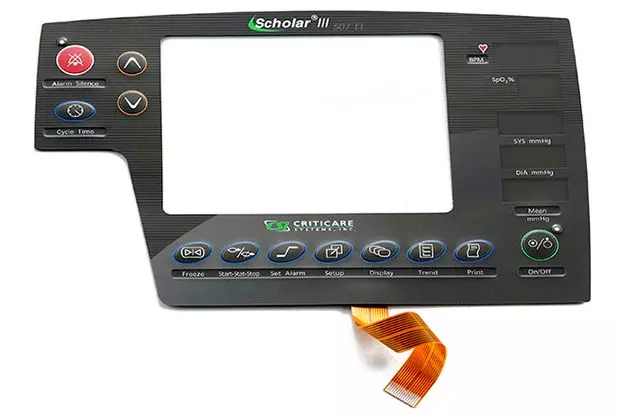

DetailsPCB assembled membrane switch

Printed Circuit Board 0505

Membrane switch circuit layer with metal dome,Metal dome assembled underneath to make good...

DetailsControlling device Silicone Rubber Keypad

Silicone Rubber Keypad 0302

Controlling device Silicone Rubber Keypad uses the compression molding properties of silicone...

Details

Facilities Translucent Rubber Keypad | Durable Keypads for Any Environment - Manufacturer Direct | YiYi Enterprise Co., Ltd

Located in Taiwan since 1974, Yi Yi Enterprise Co., Ltd. has been a membrane switch manufacturer. Their main products include, Facilities Translucent Rubber Keypad, waterproof membrane switches, membrane switch keyboards, tactile membrane keypads, graphic design overlay, mechanical membrane keyboards, custom aluminum nameplates, cutout EL panels, industrial silicone rubber keypads and rigid-flex PCB design and fabrication, and all the materials and components are RoHS compliant.

Yi Yi is expert in manufacture of membrane keyboard switches, flexible printed circuits, rigid-flex board, el panels, silicone rubber keypad and name plates. We have acquired the skills and technology necessary to produce top-quality products that are suitable for use in computers, instruments and other electronic and electrical goods.

YI YI has been providing customers with membrane switches, both with advanced technology and 49 years of experience, YI YI ensures that each customer's requirements are met.